Product Development Group

IDEA' s & INVENTION STRATEGIES IN MOTION

Issues - Strategies - Solutions - Resources

Strategies For Inventors

Five Things To Consider About

Development Of Your Invention

Taking inventions from concept to reality can be difficult. In fact, it's quite confusing. Many Inventors have been down that path several times, and without help simple matters become daunting. Many Inventors have also attempted to go it alone and spent tens of thousands with a prototyping house, an engineer and more. Outside of finances, many Inventors have faced challenges when deciding who to talk to, how to patent and the path they should take when pursuing their inventions.

Thinking of these subjects,

GatewayProductDevelopmentGroup.com has compiled a list of five things to consider about your inventions.

1. Know the problems your invention will solve

Every invention or great idea aims to solve a problem. Everyday people recognize problems on a regular basis. Inventors choose to solve them.

Before pursuing your idea, clearly understand the problem your invention will solve. Does your solution work? Does your invention need a little help? Is it too complicated? Working with a trusted company that understands design and engineering helps clarify problems and reveal solutions.

2. Your invention's market

Once you know the problem your idea will solve, begin thinking of the market in which you invention would sell. Is it a home product? Maybe it's an automotive invention? Will it stand alone in its own category?

Understanding your invention's market, will help you in every step you take. You can now compare it to other products in that category and the companies that make those products. This will help you later when identifying a company you'd like to see license your invention.

3. Invention security

If you choose to disclose your invention idea with someone, whether it be family, an attorney or a company you hope to work with, security should always be on your mind. An inventor's greatest fear is losing their invention idea to someone else.

The most dangerous times can be when you deal with an outside company to help you with your invention. Always ensure they have security precautions in place to protect you and your invention. Don't sign anything unless it explicitly states it's there for your protection.

Protect your invention with a confidentiality agreement that everyone must sign. Make sure you sign an Idea Security Agreement with anyone you choose to work with. This is an extra layer of protection for your invention.

When dealing online, you should ensure it's a legitimate company. Always look to see if they have established security systems. Some invention companies exist solely on the Web, lacking roots in a community. Before sending your invention information out, make sure you know they use a trusted secure server or security system.

4. Product sales sample - A working invention

We believe that a product sample is vital to the success of an invention. Without a product sample, you won't truly be able to understand the invention's function, manufacturability and you'll have difficulty holding a business conversation.

Building the product sample takes good design work, engineering and prototyping, each of which can become quite expensive on their own. As well, jumping between these entities causes confusion that could damage the value of your invention. It's much like the telephone game we played in elementary school with our peers. With each additional person speaking for you, your invention's message gets lost. Keeping all these necessary processes together, keeps your vision aligned.

5. How to patent

Often the first thing on an inventor's mind when they finish their creation is how to patent. Perhaps a more pertinent question should be "When should I patent?" or "Am I really done inventing?"

There are a lot of companies that push inventors to patent their invention idea immediately. Unfortunately, patenting is a costly and time-consuming process that far too often results in frustration when an inventor discovers they have to change their invention to either interest a buyer or make it manufacturable.

One of the reasons we encourage fellow inventors to prepare a product sample is to identify unique areas of the invention that further protect it in a patent. This also keeps competitors and those who may seek to knock off your invention at bay.

When pursuing your invention, keep these five invention tips in mind to help you save yourself time, effort and money, as well as protecting you at one of the most vital times in the development of your idea or invention. Keep in mind the protection of you and your invention remains of the utmost importance to you above all else.

Thank You for visiting us to learn how to bring your idea, invention, product or service to the marketplace!

CREATING A NEW INVENTION?

GatewayProductDevelopmentGroup.com is here to guide you,

through education and intelligence, with each step of the product

design & development process you need to be successful.

From invention to prototype, to manufacturing, we'll

present the help you need to make your awesome

and dynamic new product the best it can be.

"Our passion on this site is real time product development

in Motion," says Founder and President JW Davis.

Services Needed For Inventors

To Succeed Include:

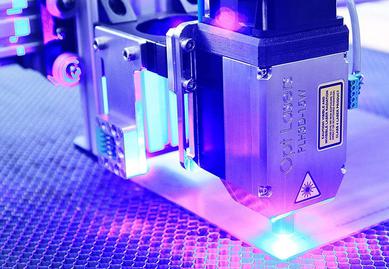

* 3D Laser Scanning of Existing Components

* 3D Printing, Rapid Prototyping, & Additive Manufacturing

* CAD Design & 3D Modeling Services

* Competitive Product Benchmarking Review

* Contacts within our Network of Entrepreneurial Resources

* Converting 2D Drawings/Prints to 3D CAD Models

* Detailed Dimensioned Drawings/Prints for Manufacturing

* Free Phone & In-person Consultation

* Industrial Design (aesthetics) for Product Marketability

* Manufacturing & Production Assistance

* Photo-realistic CAD Model Renderings for Sales & Marketing

* Product Design & Development

* Project Scope, Strategy, Planning, & Budget Creation

* Prototype Development

Read On to Learn More

About Strategies For Inventors

New to Product Development?

We’re dedicated to helping educate inventors.

The knowledge and intelligence we cover here includes a wide range of product development procedures, intellectual property measures, and technologies

available to make new product ideas and inventions to help you bring

your invention to the consumer market in a timely manner.

Need help with a product

design project for your company?

If your company needs temporary or long term expert CAD Designers or

Product Design & Development assistance, visit our “Services for Companies”

page to learn more about utilizing a highly skilled team for your project.

Email us at admin@GatewayProductDevelopmentGroup.com,

or Contact us using the simplified form below,and we’ll gladly help.

GATEWAY

3D Laser Scanning Process

3D laser scanning is a non-contact process that uses lasers to capture precise 3D data of physical objects or environments, generating a detailed digital replica called a point cloud. This technology is vital for creating accurate as-built models for renovations, reverse engineering legacy components, ensuring quality control, and facilitating design for modifications or new construction. It significantly improves efficiency and accuracy in industries like construction and manufacturing by minimizing errors, reducing rework, and enabling better planning and clash detection between new and existing structures.

How it Works

Laser Emission: A laser beam is emitted from the scanner and directed towards an object or surface.

Reflection & Capture: The laser light reflects off the object's surface and returns to the scanner.

Data Calculation: By measuring the time it takes for the light to return and combining it with angular information, the scanner calculates a precise distance to the object's surface.

Point Cloud Creation: This process is repeated millions of times, with each measurement forming a point in a dense 3D point cloud, which is a digital representation of the object's shape and geometry.

Key Applications

Construction: As-Built Documentation: Captures the exact current state of a building for renovations, retrofitting, and facility management.

Clash Detection: Compares scanned data with BIM models for new construction to identify interferences before construction begins.

Accurate Documentation: Provides precise measurements for shop drawings, quantity takeoffs, and construction documents.

Manufacturing:

Reverse Engineering: Creates digital models of existing or legacy parts to replicate, modify, or design aftermarket components.

Quality Control: Performs dimension analysis and quality assurance to ensure manufactured parts meet specifications.

Other Applications:

Digital Twins: Generates detailed 3D models that can serve as the foundation for creating virtual reality environments and simulations.

Preservation: Captures historical structures to create accurate digital archives.

Benefits

Accuracy & Precision: Delivers highly precise and detailed data, often achieving accuracy within millimeters.

Efficiency: Speeds up the measurement collection process, reducing time and effort compared to traditional methods.

Error Reduction: Minimizes errors and rework by providing exact as-built conditions, which is critical for complex projects.

Non-Contact: The non-contact nature ensures that delicate, complex, or functional components are not skewed or damaged during measurement.

Enhanced Planning: Facilitates better design and planning through highly accurate and detailed digital models.

3D Lazer Scanning Technology Overview

3D laser scanning captures the precise geometry of existing components by collecting millions of data points to create a digital model, known as a "point cloud". This non-contact, non-destructive technology is used across many industries for tasks like reverse engineering, quality inspection, and documenting as-built conditions.

How the process works

The workflow for 3D laser scanning can be broken down into three main phases:

Data capture: A laser scanner projects laser beams onto the surface of a physical object or environment. There are three main types of scanners based on the technology used to measure the reflection:

Time of Flight: The scanner measures the time it takes for a laser pulse to travel to the surface and back to determine the distance. This is often used for large-scale environments.

Phase Shift: The scanner compares the phase of the emitted and returned laser light to calculate distance with very high precision, though typically over a shorter range.

Triangulation: The scanner projects a laser line or pattern, and a camera records the reflection from a known angle. Trigonometry is then used to calculate the position of points on the surface.

This is ideal for smaller objects that require high resolution.

Data processing: Multiple scans are taken from different positions to capture all angles and are then aligned, or "registered," to form a single, cohesive point cloud.

Specialized software cleans up the raw data by removing unwanted "noise," such as stray reflections, and merges the scans into a unified dataset.

Model creation and analysis: The raw point cloud is used to create various deliverables, such as 3D mesh models, 2D drawings, or Building Information Models (BIM).

The digital model can then be used for analysis, such as comparing it against original design plans to identify any deviations or clashes.

Key applications

Reverse engineering: Creates 3D CAD models of legacy parts that have no existing design data, allowing for replication or modification.

Quality control and inspection: Allows for precise measurement and comparison between a manufactured part and its original CAD model to ensure dimensional accuracy.

Construction and architecture: Documents the "as-built" condition of structures for renovations and retrofits. This is crucial for clash detection between new designs and existing infrastructure.

Heritage preservation: Creates accurate digital archives of delicate artifacts or historical sites without physical contact.

Industrial manufacturing: Facilitates the redesign and expansion of manufacturing facilities by providing accurate layout data.

Advantages and limitations

Advantages: High accuracy and detail: Scanners can capture millions of data points with submillimeter to millimeter-level precision.

Speed: Data can be captured in a matter of minutes or hours, which is much faster than manual measurement methods.

Non-contact and non-destructive: The technology is ideal for scanning fragile or complex components without causing damage.

Enhanced safety: Technicians can capture data from a safe distance, reducing the need to enter hazardous or hard-to-reach areas.

Reduced costs: By minimizing measurement errors and reducing project timelines, laser scanning can cut down on expensive rework and delays.

Limitations: Line-of-sight: The scanner cannot capture data for features that are hidden or out of its line of sight, such as internal geometry.

Environmental factors: Ambient light, reflective surfaces, and weather conditions can interfere with the scanner and reduce accuracy.

Cost: Industrial-grade scanners and software can be a significant investment.

Expertise: Operating the equipment and processing the complex point cloud data requires specialized skills and training.